PVC Corrugated Pobzeb Extrusion Kab

Khoom taw qhia

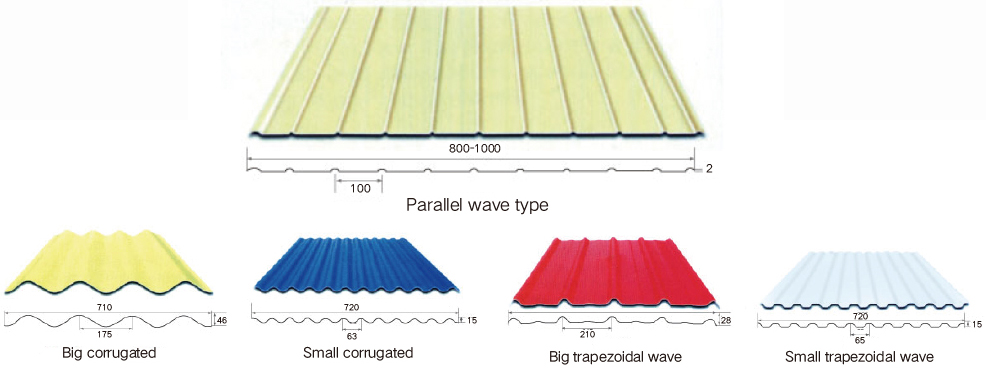

Raws li kev hloov ntawm galvanized steel pobzeb, corrugated pobzeb tau txais ntau thiab ntau daim ntawv thov nyob rau hauv lub tsev tsim, Grace customizes txawv kev daws teeb meem raws li cov neeg xav tau ntawm cov khoom qauv, cov duab uas muaj dav ntawm 720mm mus rau 1130mm thiab thickness ntawm 0 8mm mus rau 3 0mm. Raws li cov kev nyiam tshwj xeeb ntawm cov cheeb tsam sib txawv, Grace tsim cov qauv puag ncig yoj hom thiab cov duab trapezoidal Tshwj xeeb alloy ua cov ntsia hlau thiab lub thoob tuaj yeem ua tau raws li 80-100phr siab sau cov qauv tsim cov kev cai Calibration pwm txais kev tsim tshwj xeeb ntawm cov dej ntws, nce qhov chaw ntawm cov dej txias thiab cov khoom kawg, uas txhim kho cov nyhuv txias thiab kev sib sau ceev, Lub sijhawm no, Plua plav-dawb cutter yog cov tshuaj zoo meej rau kev txiav cov nplais ru tsev.

Tus nqi kom zoo dua

1. Kev tsim tshwj xeeb ntawm cov ntsia hlau, uas tuaj yeem ua kom cov khoom zoo meej plasticizing thiab qis dua tus nqi tsim khoom; Nyob ntawm qhov kev thov ntawm cov mis sau siab, SKD61 (Nyiv lossis Lub Tebchaws Yelemees) cov khoom siv tuaj yeem nrog lub tes tsho alloy kho lub thoob tuaj yeem muab cov tshuaj ua ntej.

2. Co-extruder nruab nrog dehumidifying thiab ziab tshuab tuaj yeem siv los tsim cov khoom siv PMMA / ASA, uas ua kom muaj kev ua haujlwm siab thiab zoo ntawm cov khoom kawg.

3. T-tuag txais yuav hanger style tuaj yeem siv los tsim ib qho PVC yaj cov khoom siv ntau txheej lossis cov khoom siv ntau txheej.

Cov pwm ntws nto txais kev kho polish thiab electrochromism, uas ua kom muaj dej zoo thiab zoo tiv thaiv corrosion, kub-tiv taus thiab hnav tsis kam ua haujlwm.

4. Distributor feem ntau siv rau hauv ntau txheej txheej txheej txheem. Nws muaj ob peb cov qauv xws li A / B, A / B / A, A / B / C thiab lwm yam. Lub hom phiaj tseem ceeb yog ua kom zoo meej muaj pes tsawg leeg ntawm cov khoom sib txawv.

5. Calibration forming table suav nrog peb ntu: calibration pwm, tshem tawm thiab txiav, Kev tsim pwm yog tsim los ntawm Up thiab Down pwm, ntws nto txais polish thiab electrochromism kev kho mob, uas tuaj yeem ua kom zoo heev liquidity thiab zoo anticorrosion,tshav kub-resisting, hnav-resisting kev ua tau zoo.

6. Cov qauv tsim channel yog S zoo los ua kom muaj kev sib cuag ntawm cov pwm, uas ua kom cov cua sov hloov mus sai thiab ua kom txias sai. Txhawm rau kom muaj kev ruaj khov siab dua, cov duab ntawm cov menyuam roj hmab (thawj tawm) tsim raws li cov khoom kawg, Lub cutter txais hom sawing thiab cov duab ntawm cov hniav tsim raws li cov khoom kawg, uas ua rau lub tiaj thiab nti dawb txiav.

Technical parameter

| Qauv | Khoom siv | Dav | Thickness | Extruder qauv | Tsim tawm |

| Ib Txheej | PVC | 720/920/1100/1130 hli | 1.0-3.0 hli | SJZ80/156 | 350-400kg / h |

| Ob txheej txheej | ASA / PMMA + PVC | 720/920/1100/1130 hli | 1.0-3.0 hli | SJ50/30+ SJZ80/156 | 350-400kg / h |

| Triple Txheej | ASA / PMMA + PVC + PVC | 720/920/1100/1130 hli | 2.0-3.0 hli | SJ50/30+SJZ65/132+SJ51/105 | 350-400kg / h |

| Triple Txheej | PVC + PVC ua npuas ncauj + PVC | 720/920/1100/1130 hli | 2.0-3.0 hli | SJ51/105+SJZ65/132+SJ51/105 | 350-400kg / h |